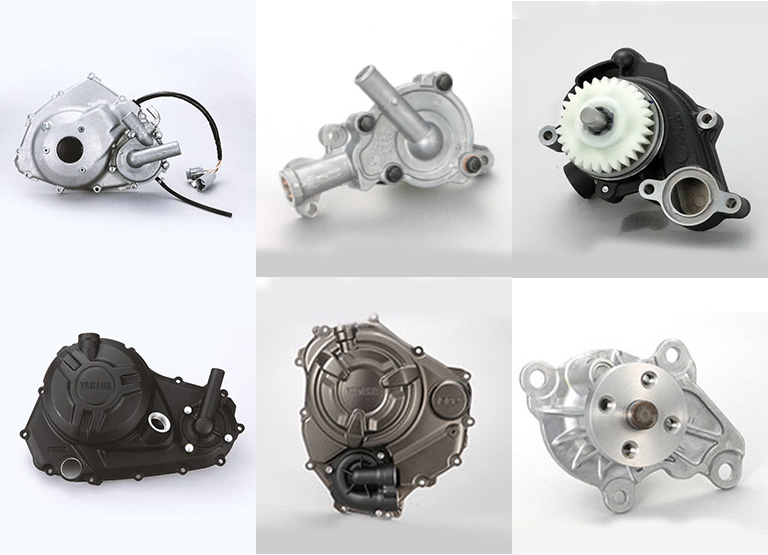

Water Pumps and Oil Pumps

stage to mass production. By utilizing front-loading techniques, we efficiently address potential issues such as

defects, variability, and waste during mass production. Additionally, we meet customer needs through

cutting-edge simulation technologies, advanced production equipment, and the latest techniques, all aimed at

delivering low-cost, high-efficiency, and high-quality products.

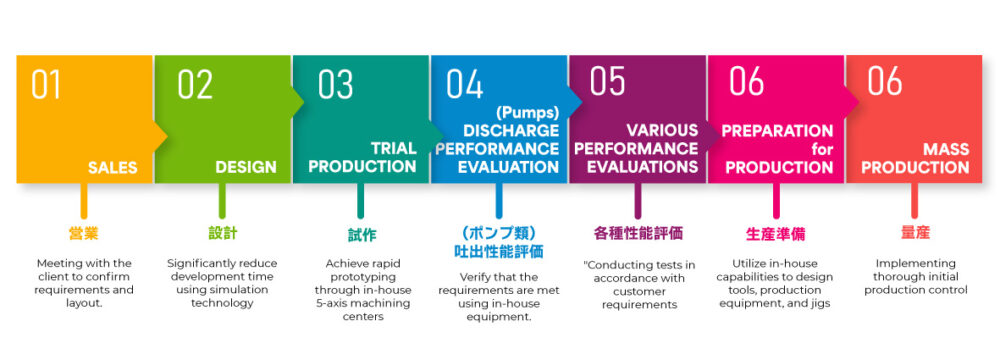

Automotive Parts Development Flow

Analysis Technology

Our analysis technologies are utilized in the design phase of parts and products to evaluate performance, predict

potential issues, and make necessary improvements.

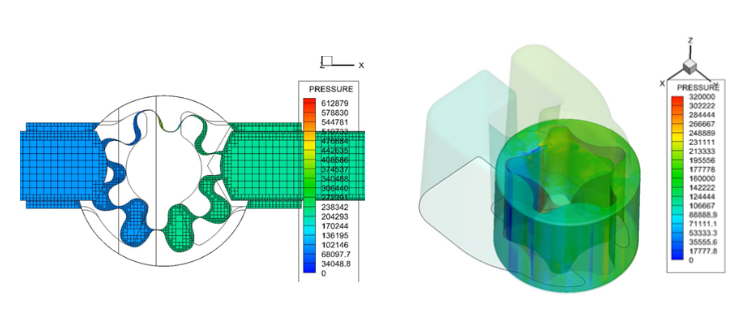

Fluid Analysis

Fluid analysis is a technology used to numerically analyze the behavior and properties of fluids, such as flow,

pressure, and velocity. This analysis is applied in the design and improvement of products involving fluids,

such as pumps, to enhance their efficiency and discharge performance.

We use fluid analysis results to optimize pump efficiency and provide feedback based on the outcomes.

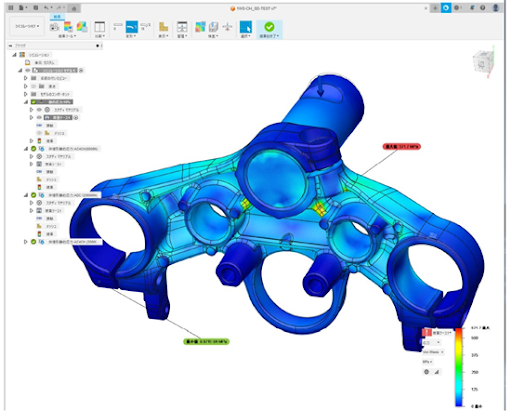

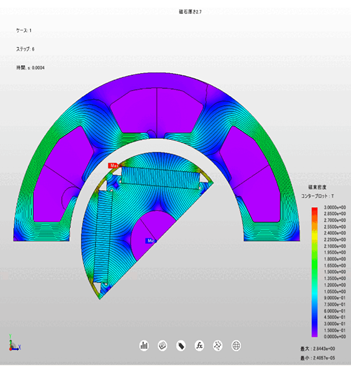

Structural Analysis

Structural analysis evaluates the mechanical behavior of objects and structures under stress, deformation, and

vibration. This analysis models how a structure responds to loads and assesses its stability and strength.

Structural analysis is widely used in various fields such as aerospace, automotive, and machinery parts, aiding

in product design improvements and durability enhancements.

We utilize this analysis to verify the safety characteristics of high-strength components and provide feedback to

our customers.

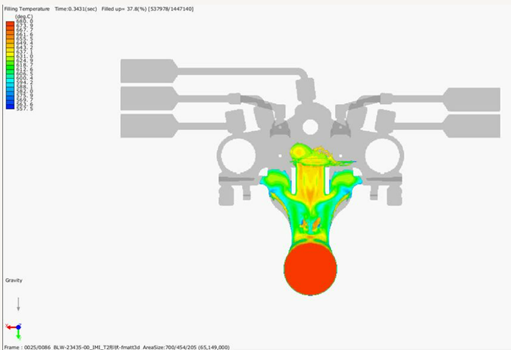

Casting Analysis

Casting analysis is used to evaluate the flow, cooling, and solidification processes during casting. This

analysis predicts how molten metal flows and forms within the mold, helping assess the quality and shape of cast

products. It also helps in predicting internal defects and improving the overall quality and production

efficiency of cast products.

Through casting analysis, we work to improve yield, reduce internal defects, and explore high-cycle production

methods.

Magnetic Field Analysis

Magnetic field analysis evaluates the behavior of objects and components in electromagnetic fields. It models

factors such as electromagnetic field strength, distribution, and magnetic flux density. This analysis is

commonly used in the design and performance evaluation of electromagnetic devices, such as electric motors and

electrical equipment.

With the growing trend of automotive electrification, we are actively advancing the development of electric

pumps. We offer comprehensive development services, from motor design to final product, tailored to meet

customer needs.

Testing Equipment

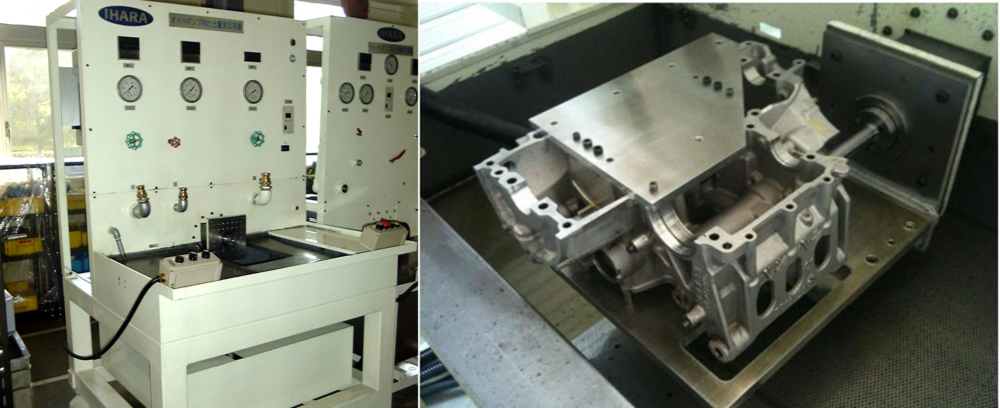

Flow Rate Testing

Flow rate testing evaluates how much fluid a pump can discharge under specific pressure conditions. During this

test, fluid is supplied to the pump, and the flow rate output is measured at a given pressure. Flow rate testing

helps assess pump performance and efficiency, contributing to design optimization and performance improvements.

Durability Testing

Durability testing evaluates whether parts or products can withstand long-term use. For pumps, this involves

continuous operation to assess wear, fatigue, and other forms of degradation. It can also detect issues such as

abnormal vibrations or temperature increases. Durability testing results provide valuable insights into the

product’s durability and reliability, helping identify areas for improvement.

Our Commitment to Technology and Service

By leveraging advanced analysis technologies and testing equipment, we deliver low-cost, high-efficiency, and

high-quality part development that meets customer needs. Through our reliable water pumps and oil pumps, we

strive to enhance customer satisfaction by continuously pursuing the latest technologies and applying our

extensive expertise to optimize quality and efficiency. Expect nothing less than the best from our technical

capabilities and services.