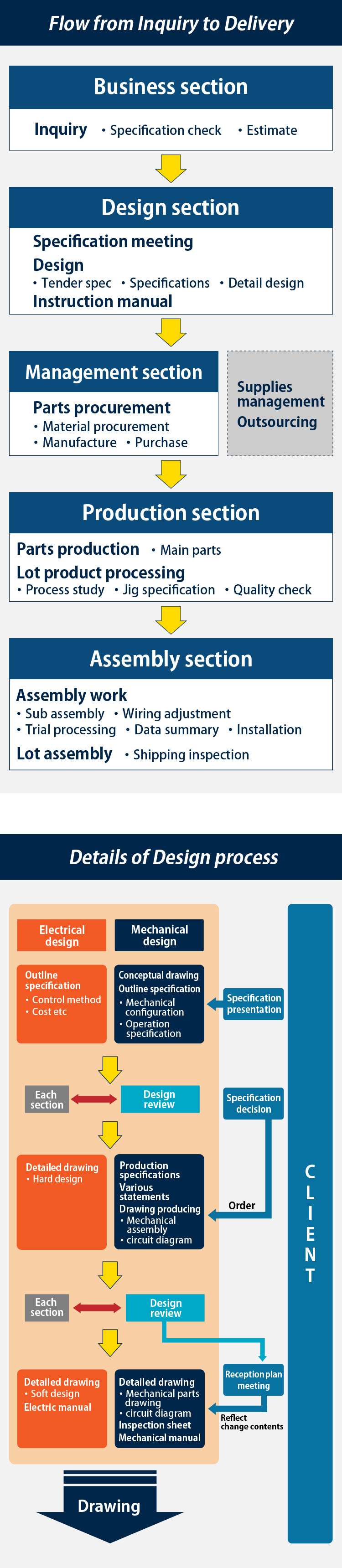

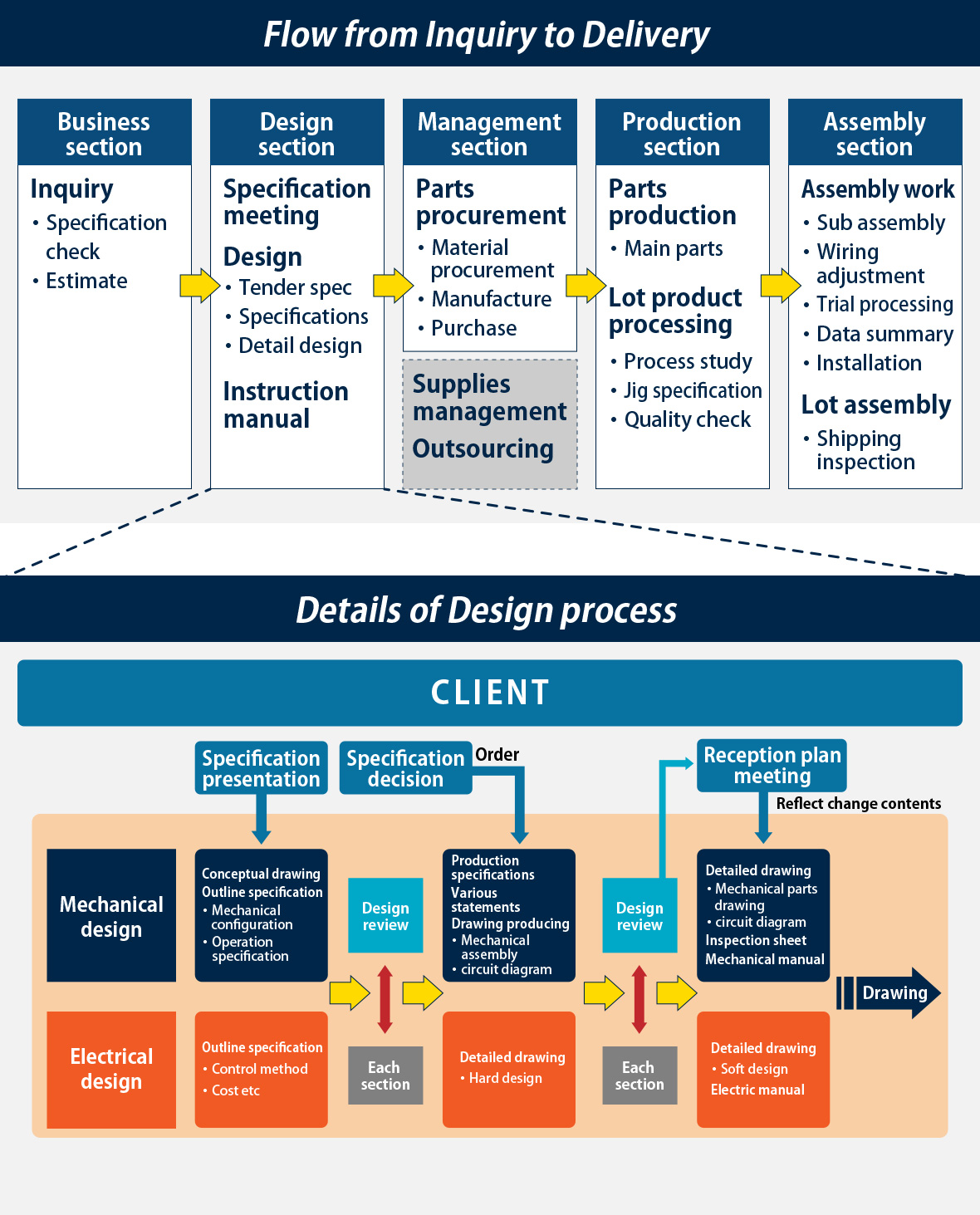

Development and production process

-

1.Customer requirements

We develop parts which meet cost, quality and short time delivery and achieve green procurement.

-

2.Meeing of specifications

We have adopted the CE system, ask customer(designer) required perfomance and layout information of the products prior to finalize drawing.

-

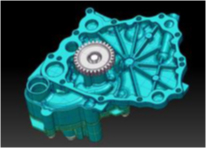

3.3D & 2D design

Create solid model in 3D, study the machining and assembly process or interference, then finally issue the receipt drawing.

-

4. Prototyping

Parts that are designed with solid model is cut by own made machining center with CAD/CAM,therefore achieve short time prototype process.

-

5.Discharge performance confirmation

Check whether meet planned discharge amount with in-house equipment. Then supply the prototype parts to coustomer.

-

6.Various durability evaluation (by customer request)

Along the customer’s needs, conduct a variety of reliability tests such as endurance test.

-

7.Decide specification

While taking perfect confidentiality, we develop in accordance with the customer’s development schedule.

-

8.Recipt drawing

we are working on proposal development. we are always positively and develop to lead to the good results.

-

9.Production preparation

Making use of machine-maker’s advantage, we have designed production process and manufactured machines and jigs.

Mass production