Aluminum Die Casting & Machining

High-Cost Competitiveness and Quality Product Manufacturing

We continuously strive to create high-quality products with strong cost competitiveness, allowing our customers

to entrust their aluminum die casting needs with confidence. Below are some examples of our efforts.

-

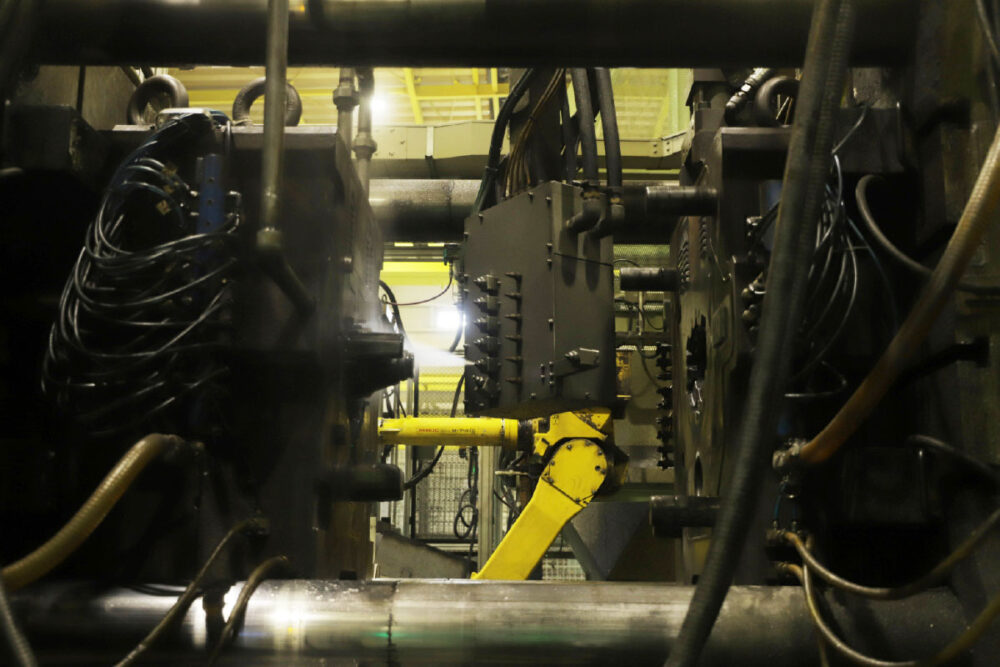

In-House Production Line Design & Manufacturing

To efficiently produce high-quality aluminum die cast parts, we design and manufacture all

production lines and auxiliary equipment in-house, always optimizing our manufacturing

processes. -

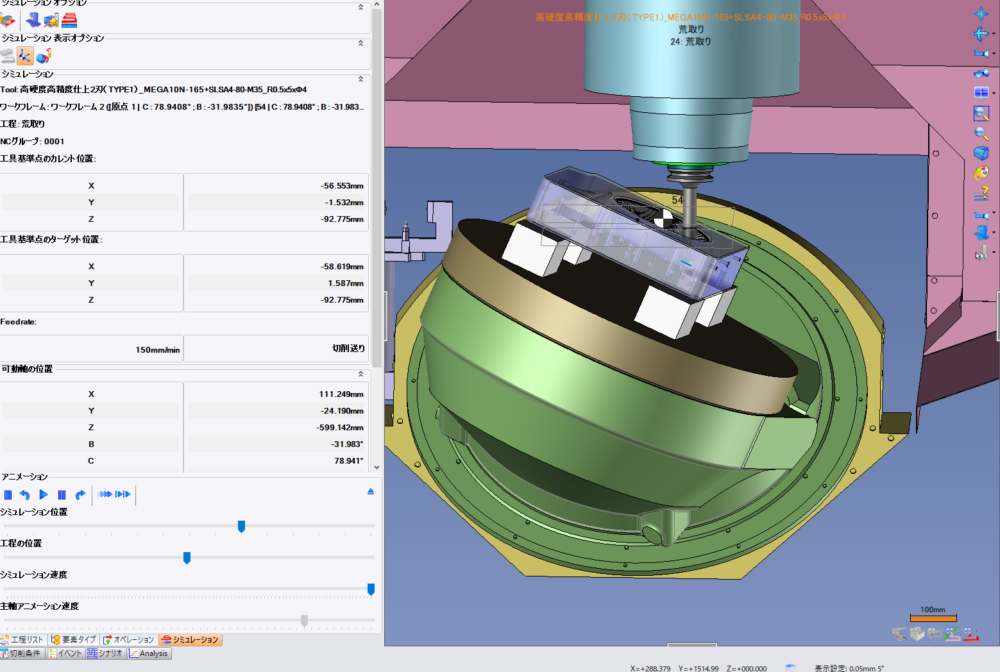

In-House Mold Design & Manufacturing

We also design and manufacture some of the molds used in our production lines, reducing lead

times and costs during the startup and troubleshooting phases. -

IoT Implementation for Monitoring Production

We have implemented IoT technology that enables us to monitor operating conditions, yield rates,

error statuses, and casting parameters at a glance, allowing for quick responses and

improvements. -

3D Measurement and CT Scanning

To ensure the high quality of our aluminum die cast parts, we have introduced 3D measurement

devices and CT scanners to inspect internal defects. -

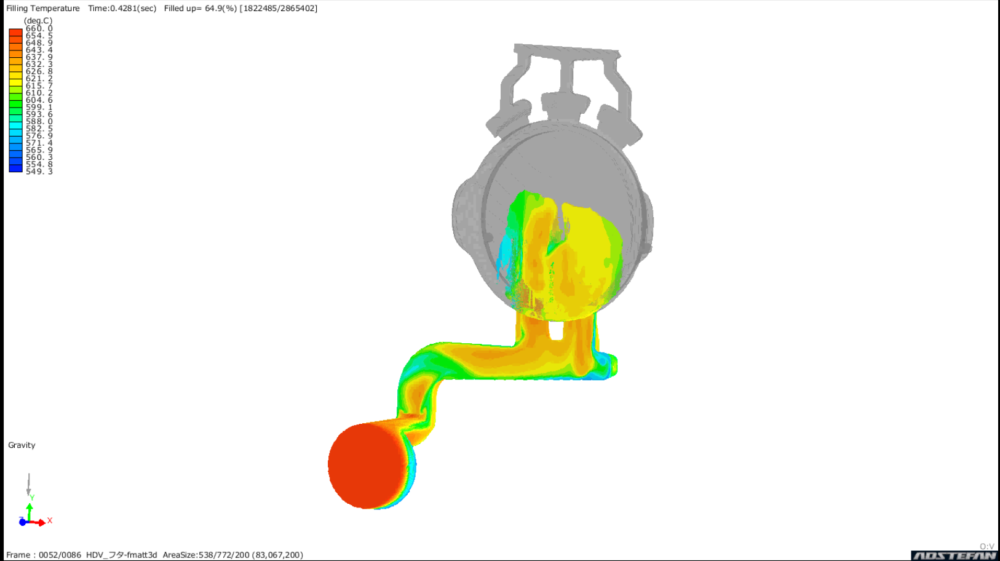

CAE Simulation

We perform fluid analysis (CAE) to design optimal casting methods, improve quality, and reduce

costs (e.g., lightweight product designs).

The Great Potential of Aluminum Die Casting

Aluminum die casting is used in various fields, with the automotive industry being the largest market. As the

industry shifts towards electric and fuel cell vehicles (EVs and FCVs), reducing vehicle weight to extend range

and improve fuel efficiency becomes critical. Aluminum, known for its lightweight and high heat dissipation

properties, plays a key role in addressing this need. Furthermore, aluminum is highly recyclable, making it an

environmentally friendly material. At Ihara Manufacturing, we leverage the strengths of aluminum die casting to

contribute to a better society through continuous innovation.

What is Aluminum Die Casting?

Aluminum die casting involves casting products by injecting molten aluminum alloys into molds at high speed and

pressure. This method results in products that are lightweight yet strong, with high thermal and electrical

conductivity. Aluminum die cast products are widely used in automotive parts, machinery, electronics, and more.

Aluminum Die Casting Manufacturing Process

At Ihara Manufacturing, many of our processes for aluminum die cast part production are automated, ensuring both

high productivity and quality.

-

1.Aluminum Melting

Aluminum ingots and return materials are melted in a furnace.

-

2.Pouring Molten Aluminum into Casting Machines

The molten aluminum is poured into the die casting machine.

-

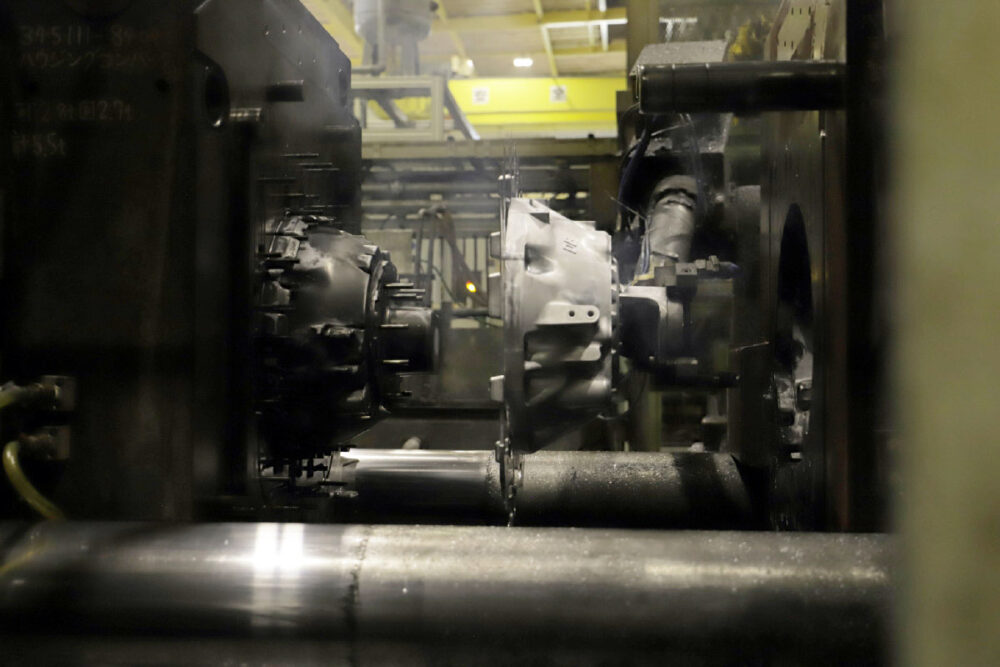

3.High-Speed, High-Pressure Casting

The molten aluminum is injected into the molds at high speed and pressure.

-

4.Robotic Removal

The molded aluminum die cast products are removed by robots.

-

5.Mold Release Agent Application

A release agent is applied to the mold to make it easier to remove the next casting.

-

6.Trimming

Excess material, such as runners and overflow, is removed from the cast parts.

-

7.Cooling

The products are automatically transported on cooling conveyors.

-

8.Deburring with Robots

Burrs are removed automatically using robots equipped with deburring tools.

-

9.Shot Blasting

Small metal balls are blasted at the products to remove fine burrs.

-

10.Product Inspection

Dimensional inspections are conducted as necessary, and final quality checks are performed

visually.

Advantages of Aluminum Die Casting

The reason why aluminum die casting is used in many fields is because it has many advantages. I have summarized

the benefits.

-

Lightweight

Aluminum die cast products are lightweight, making them ideal for products and parts that need to

minimize weight. -

High Strength

Despite being lightweight, aluminum die cast products offer high strength and durability.

-

Excellent Mass Production Capabilities

Once a mold is created, identical products can be mass-produced efficiently.

-

Precision in Shape

Die casting allows for precise, complex shapes, making it suitable for products requiring high

dimensional accuracy and a smooth surface finish. -

High Thermal and Electrical Conductivity

Aluminum alloys effectively conduct heat and electricity, making them suitable for engine parts and

components used in electric vehicles. -

Environmentally Friendly

Aluminum is highly recyclable without degradation in quality, making it an environmentally sustainable

material.

Disadvantages of Aluminum Die Casting

Aluminum die casting has many advantages, but it also has some disadvantages compared to other materials. I have

summarized these points.

-

Internal Quality Defects

Aluminum die cast products may have internal defects like porosity, making them less suitable for

applications requiring high pressure resistance. -

High Initial Costs

Die casting requires expensive molds, leading to high initial costs, especially for small production runs

or products with many variations. -

Limited Strength Compared to Steel

While aluminum offers many advantages, it is not as strong as steel, limiting its use in high-strength

applications. -

Low strength compared to steel etc.

While aluminum is lightweight, it has lower strength than other metal materials such as steel, so it may

not be suitable for certain applications where high strength is required.

Differences Between Die Casting and Other Casting Methods

Besides die casting, there are other methods such as sand casting, gravity casting, and low pressure casting,

each of which has different manufacturing methods, characteristics, and advantages. I have summarized the

differences between them.

Die Casting

Molten aluminum is injected into molds under high pressure, allowing for precise shapes and complex designs. It

is ideal for mass production but requires expensive molds.

Gravity Casting

Molten aluminum is poured into molds using gravity. While the process allows for better internal quality and

lower mold costs, it lacks the dimensional accuracy of die casting.

Sand Casting

A casting method using sand molds, which are less expensive than metal molds, making this method ideal for

prototypes and small runs. However, it is not suitable for mass production due to the lower surface finish and

dimensional accuracy.

Leave Your Aluminum Die Casting Needs to Us

With years of experience and a solid track record in aluminum die casting, Ihara Manufacturing offers

high-quality and cost-effective solutions to meet your needs. We handle every stage of production, from research

and development to prototyping and testing. If you are looking for a reliable partner for aluminum die cast

parts, feel free to contact us.