Machine Tools, Robots, and Automation Equipment Setup

Experience and Production Technology Gained from Our Own Mass Production Business

Our sales and technical staff, who have gained experience in production technology through mass production

operations, listen to customer needs and offer solutions. We provide full know-how in automation, labor-saving,

quality stabilization, and efficiency improvement, including robots, tools, poka-yoke systems, and energy-saving

equipment.

Total Setup

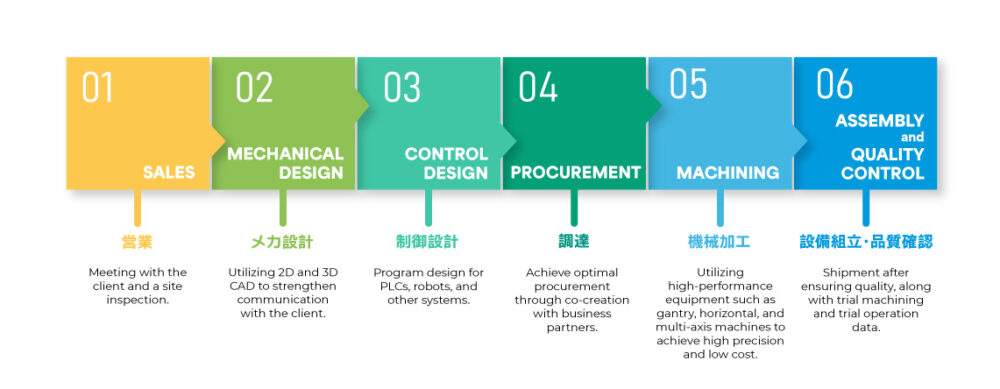

Ihara Manufacturing offers a total setup service for machine tools and related equipment (automation,

transportation, and inspection equipment) based on our extensive experience and expertise. From design,

procurement, assembly, to on-site installation, we provide one-stop solutions, adjusting everything to the

point where the customer simply needs to press the start button. This service helps reduce the burden of

managing and coordinating multiple suppliers, leading to significant cost savings for our customers.

We can solve the following issues:

- Lack of personnel to set up a new production line

- Unstable product quality

- Imbalanced production lines

- Difficulty in finding specific methods for energy-saving or efficiency improvements

- Rising maintenance costs due to aging equipment

- Need for flexible production lines to handle product diversification

Services Offered

We provide effective solutions to adapt to market changes and demands in your factory and production lines.

1. Design and Manufacturing of Machine Tools and Production Lines

We offer customized solutions tailored to customer needs.

Customization Options

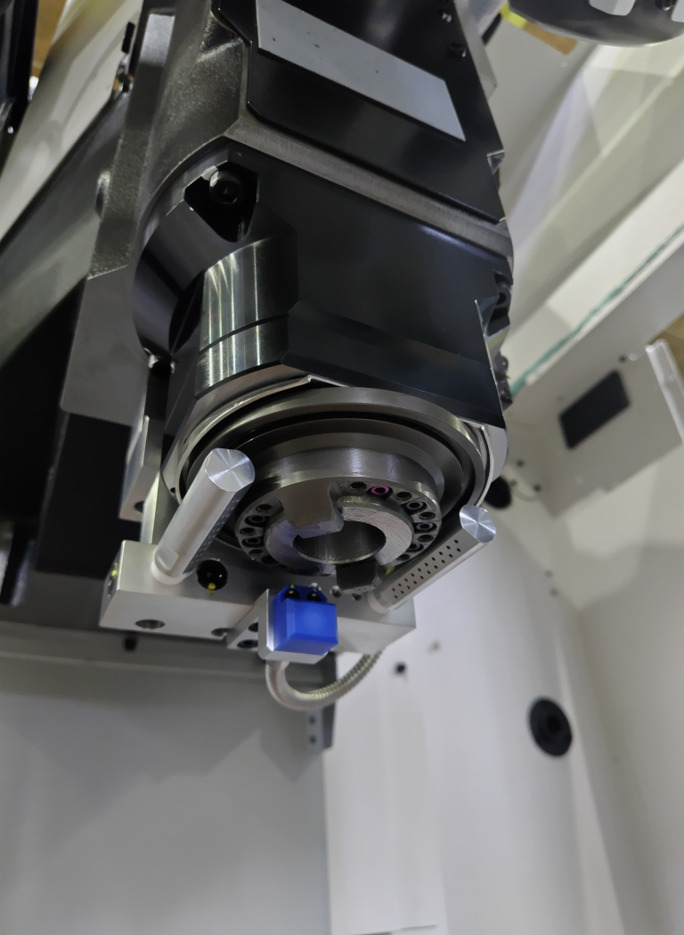

Additional Spindle Unit

Runout Detection Device

Oil Mist Installation

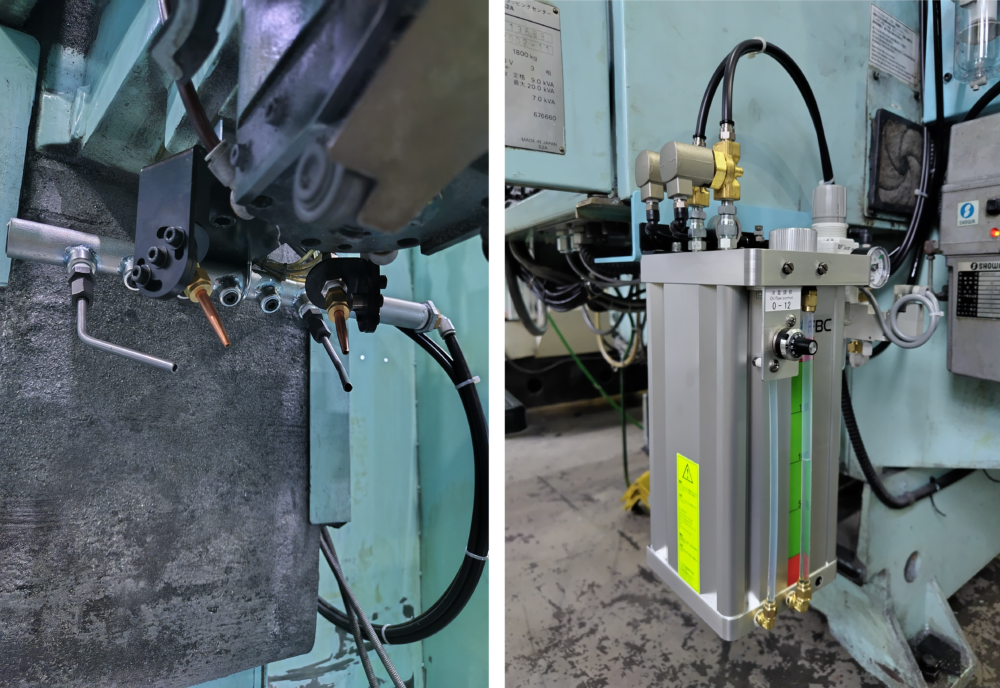

2. Assembly Equipment and Inspection Devices

We provide various equipment for assembly, such as parts pressing, as well as inspection devices for pressure

leak tests and visual inspection.

Assembly/inspection equipment

Image inspection device

Solution Examples

-

Automated Machining Center Line

Customer Challeng

In response to producing over 100,000 units per month, the customer wanted to reduce costs by

introducing an automated line for cutting, washing, and inspection processes.Service Provided

We designed and manufactured the necessary equipment, including machining centers, gantries,

specialized washing and drying machines, and inspection machines, which helped reduce labor. -

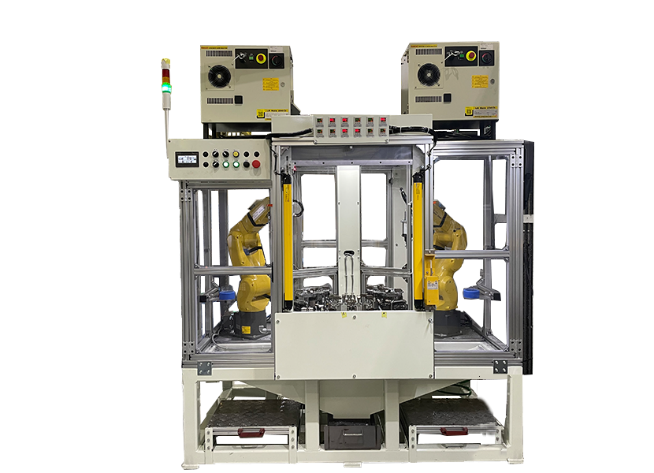

Deburring Robot

Customer Challenge

The deburring process within the line was a bottleneck, hindering productivity. There were also

inconsistencies in the finish depending on the operator’s skill level.Service Provided

Introducing robots eliminated the bottleneck and ensured uniform finishing accuracy.

-

Transport Multi-Axis Robot

Customer Challenge

The customer needed to transport heavy workpieces that multi-joint robots couldn’t handle.

Additionally, they required equipment durable enough for long-term use, as the product lifecycle

was long.Service Provided

We synchronized two SCARA robots to implement the transportation process for heavy workpieces.

Process Flow

Inquiries and Consultation

Ihara Manufacturing contributes to automation not only in the automotive industry but also in sectors such as

glass substrates, chemicals, and medical fields. Please feel free to consult with us for your automation

needs.